Contract manufacturing optoelectronic systems

Our team of experts uses high technical standards and excellent know-how to manufacture your optoelectronic products.

Complete camera production including pre-assembly

Clean room ISO class 7

Production of up to 500 modules per week

Precise active or passive alignment of optics and sensor

100 % testing of all modules produced

Labeling & documentation of all modules produced

Unique Expertise

TRIOPTICS is the best partner for your production

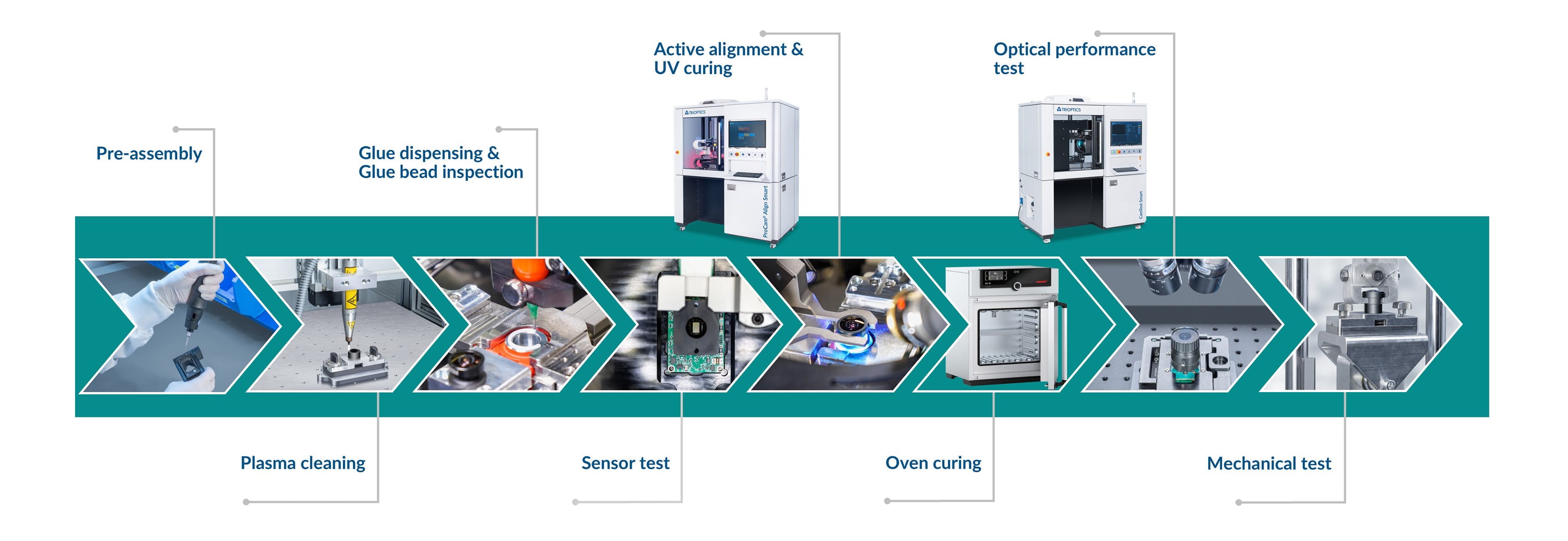

Every order begins with a detailed assessment. We work together to define each process step in detail and create customised work instructions for your project. The production steps of our service offering can be broadly divided into three categories:

Pre-assembly

Production

Our ProCam® Align Smart production system for active alignment is the heart of our manufacturing line. Here, the adhesive is first applied with microliter precision, followed by visual adhesive inspection and sensor testing. The lens is then perfectly aligned using focusable collimators and 6-axis alignment kinematics until the best possible focus is achieved. In the next step, the adhesive is pre-cured using UV light and the lens is fixed in its optimal position. The adhesive is finally cured in a separate oven.

The production of LiDAR components may require passive alignment processes, which can also be carried out in our machines.

Testing

Our range of services

Are you interested in our manufacturing services and would like to receive a quote?

Whether you need advice or already have specific requirements, we will be happy to help you!

Use our contact form and get quick feedback from our experts.